RBUE

Le Règlement Bois de l’Union Européenne (RBUE) est l’outil essentiel de l’Union Européenne pour lutter contre le bois illégal. En vigueur depuis le 3 mars 2013, il interdit la commercialisation et la circulation de bois exploités illégalement.

Se conformer au RBUE est une obligation pour toute importation de bois.

Pour cela, nous avons mis en place une démarche de vigilance active, formalisée dans un système de diligence raisonnée, selon trois étapes :

- la collecte d’informations

- l’analyse des risques

- l’atténuation des risques

Ainsi, pour chaque achat hors Union Européenne, nous évaluons le risque que le bois soit issu d’une origine illégale et nous le réduisons si nécessaire.

Le FLEGT (Forest Law Enforcement, Governance and Trade ou Application des réglementations forestières, gouvernance et échanges commerciaux) est un accord entre un pays et l’UE.

Aujourd’hui seule l’Indonésie dispose de cet accord qui permet d’assurer la légalité des bois vendus par l’Indonésie au titre du RBUE.

Charte d'engagements RSE LCB

Nous adhérons à la Charte RSE du Commerce du Bois (LCB). Cette charte s’appuie sur les objectifs de développement durable (ODD) des Nations Unies et comporte 3 piliers :

Approvisionnements durables : réduire les impacts environnementaux et sociaux à toutes les étapes du processus d’achat

Vente responsable : fondée sur une communication transparente permettant aux consommateurs de se procurer des produits aux caractéristiques explicitées et aux origines connues

Conduite des opérations : à travers une politique RSE, avec des initiatives de mesure et de réduction de l’impact carbone, d’économie circulaire ou d’insertion sociale.

La performance RSE est auditée par un organisme indépendant et accompagnée d’un logo distinctif intégrant un score allant de A à E. Nous avons obtenu la note maximale de A.

OLB

La certification Origine et Légalité des Bois développée par Bureau Veritas permet de garantir la légalité des achats bois, élément qui ne saurait être dissocié de la connaissance de l’origine géographique.

OLB est un système international basé sur :

- Une légalité stricte et complète

- Une exigence de traçabilité adaptée aux entreprises forestières

- Un suivi des bois simple et efficace (chaîne de contrôle)

La certification OLB est avant tout la reconnaissance de la légalité des conditions d’exploitation des bois puis de leur suivi dans l’industrie.

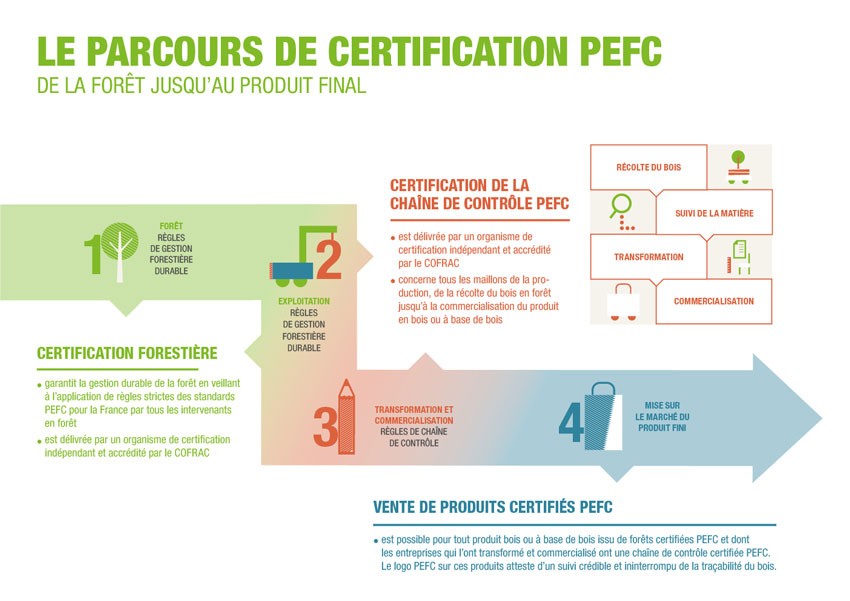

PEFC

(PEFC/10-31-772)

PEFC (Programme Européen des Forêts Certifiées) est une certification forestière avec un référentiel qui permet de favoriser l’équilibre entre les enjeux environnementaux, sociétaux et économiques.

Elle vise l’amélioration de la gestion durable des forêts au travers d’un processus volontaire d’amélioration continue. La certification forestière ne donne pas de garanties quant aux qualités technologiques mais promet une garantie et une gestion des forêts respectueuse de l’environnement, socialement bénéfique et économiquement viable.

La certification prend en compte toutes les étapes de la forêt jusqu’au produit fini :

- Forêt : Règles de gestion forestière durable

- Exploitation : Règles de gestion forestière durable

- Commercialisation et transformation : Règles de chaîne de contrôle

- Mise sur le marché du produit fini

FSC

(FSC-C004568)

Forest Stewardship Council® est une organisation non gouvernementale créée en 1993, un an aprés le Sommet de la Terre de Rio, par la volonté d’un groupe d’entreprises, d’associations environnementales (dont le WWF) et de représentants des droits sociaux.

Sa mission est de créer et promouvoir un système de certification indépendant et performant dans tous les types de forêts (boréales, tropicales et tempérées).

Un contrôle régulier des forêts et des entreprises certifiées par une tierce partie indépendante garantit l’application d’un cahier des charges de gestion responsable.

Ainsi promues par un label exigeant, les valeurs des forêts sont mieux partagées et préservées.

Bois de France

Le label BOIS DE FRANCE garantit l’origine et le lieu de transformation du bois. C’est un gage de reconnaissance du travail de la filière forêt bois française.

Aujourd’hui, les utilisateurs de bois sont de plus en plus attentifs à l’origine et au lieu de transformation du bois.

La relocalisation de l’économie est une évidence, la consommation en circuits courts également.

Avec le label BOIS DE FRANCE, les domaines de la production de bois, de la transformation, de la construction et des industries peuvent apporter ces garanties et ainsi répondre aux actuels enjeux environnementaux et sociétaux forts.

Chez Henry Timber, nous avons choisis de travailler avec le bois français et nous en sommes fiers !

Nos bois labellisés :

- Plots en chêne

- Plots en frêne

- Poutres rondes

- Planches ferrées

- Ossatures douglas

- Ossatures épicéa

- Poutres contrecollées douglas

- Lames de terrasses en douglas

- Bastaings, lambourdes, planches, madriers, planches rouges, poutres équarries, voliges, planches de coffrage en sapin

RE2020

Le bâtiment est le premier secteur en matière de consommation d’énergie avec 44%.

75% du CO2 émit par un bâtiment provient de la phase de construction.

L’enjeu majeur de la Règlementation Environnementale 2020 est de diminuer significativement les émissions de carbone du bâtiment et de mettre le secteur sur la voie de la neutralité carbone. La règlementation repose sur une transformation progressive des techniques de construction, des filières industrielles et des solutions énergétiques.

Cette règlementation du bâtiment a pour objectif de maîtriser la consommation énergétique des bâtiments neufs avec 3 objectifs :

- Des bâtiments qui consomment moins et utilisent des énergies moins carbonées

- Ménager une transition progressive vers des construction bas-carbone misant sur la diversité des modes constructifs et la mixité des matériaux

- Des bâtiments plus agréables en cas de forte chaleur

Lien vers le site : Réglementation Environnementale 2020 - RE2020

Le bilan carbone

La réalisation d’un bilan carbone a pour but d’évaluer la quantité de gaz à effet de serre dans l’atmosphère issue des activités humaines.

Pour le réaliser, il faut collecter les données d’activités de l’organisme étudié : matières premières et énergies achetées, déplacements des salariés, utilisations des produits par les clients, fin de vie des produits, …

L’entreprise peut s’appuyer sur l’Analyse du Cycle de Vie pour déterminer les impacts environnementaux des produits pour chaque phase de leur vie.

Le Bilan Carbone permet aux entreprises de quantifier leur empreinte carbone en mettant en lumière les principaux postes d’émissions (consommation d’énergie, transport, achat, déchets, …) et de mettre en place des actions stratégiques pour la réduire.

FDES

Une Fiche de Déclaration Environnementale et Sanitaire est un document qui présente les indicateurs environnementaux et des informations sanitaires d’un produit.

Il existe différents types de FDES :

- FDES de gamme : couvre un ou plusieurs produits

- FDES individuelle : couvre un produit fabriqué par un fabricant

- FDES collective : couvre un produit fabriqué par plusieurs fabricants

Une FDES est un document de plusieurs pages :

- Les premières pages sont dédiées aux informations générales sur le fabricant, le produit et le FDES

- Les pages suivantes décrivent les étapes du cycle de vie, les processus pris en compte et certaines hypothèses méthodologiques

- Le cœur de le FDES est constitué de tableaux présentant les indicateurs environnementaux par étape du cycle de vie

- Les dernières pages présentent les informations sanitaires et relatives au confort

Les FDES sont vérifiées et validées par une tierce partie indépendante et ont une durée de validité de 5 ans. Elles sont disponibles sur la base de données INIES.

Lien sur le site INIES avec une vidéo explicative : FDES (Produits de construction) - Inies

Voir les FDES collectives disponibles :

Bardage :

Construction :

Menuiserie/agencement :

Deck :

Les atouts du bois dans la construction

- Matériau biosourcé : la bois est une matière première renouvelable à l’infini

- Moins de déchets et moins d’eau : la filière bois est une filière sèche

- Légèreté : le bois est 5 fois plus léger que le béton (rotation de camions divisée par 8)

- Bénéfices carbone : Le bois piège le carbone, 1T de bois utilisé permet d’économiser 1T de CO2 par rapport à du béton

- Matériau technique : le bois est résistant au feu et isolant

- Avantages acoustiques

- Effets positifs prouvés sur la santé : la présence du bois réduit notre pression artérielle ainsi que notre fréquence cardiaque

Une forêt en pleine croissance peut absorber de 11 à 37 tonnes de CO2 par hectare et par an.

Durée de stockage de carbone dans les produits bois :

| Marché de destination finale | Emballage | Gros œuvre | Second œuvre | Meuble |

| Exemples de durée de vie type | 8 ans (palette) | 100 ans (charpente, mur ossature bois) | 30 ans (fenêtre) 100 ans (parquet massif) | 20 ans (table, meuble de cuisine) |

Glossaire

- MATERIEU BIOSOURCE : Issu de la biomasse végétale ou animale

- RE2020 : Réglementation Environnementale 2020 du bâtiment

- FDES : Fiche de Déclaration Environnementale et Sanitaire

- ACV : Analyse du Cycle de Vie

- BILAN CARBONE : Comptabilisation des émissions de gaz à effet de serre

- CARBONE GRIS : Quantité d’émission carbone lors du cycle de vie complet d’un matériau

- EMPREINTE CARBONE : Mesure des émissions de CO2 pour un produit sur tout son cycle de vie

- INIES : Base nationale de référence sur les caractéristiques environnementales et sanitaires pour le bâtiment (FDES)

- LABEL BBCA : Premier label de mesure de l’empreinte carbone d’un bâtiment

- EQUIVALENT CO2 : Unité crée par le GIEC pour comparer l’impact des différents gaz à effet de serre